One of our American customers is a company that focuses on the manufacture of high-end mechanical equipment, mainly involved in the production of industrial automation, heavy machinery and automotive parts. The customer's production line requires high-precision, high-quality metal bushings to ensure the long life and high performance of the equipment.

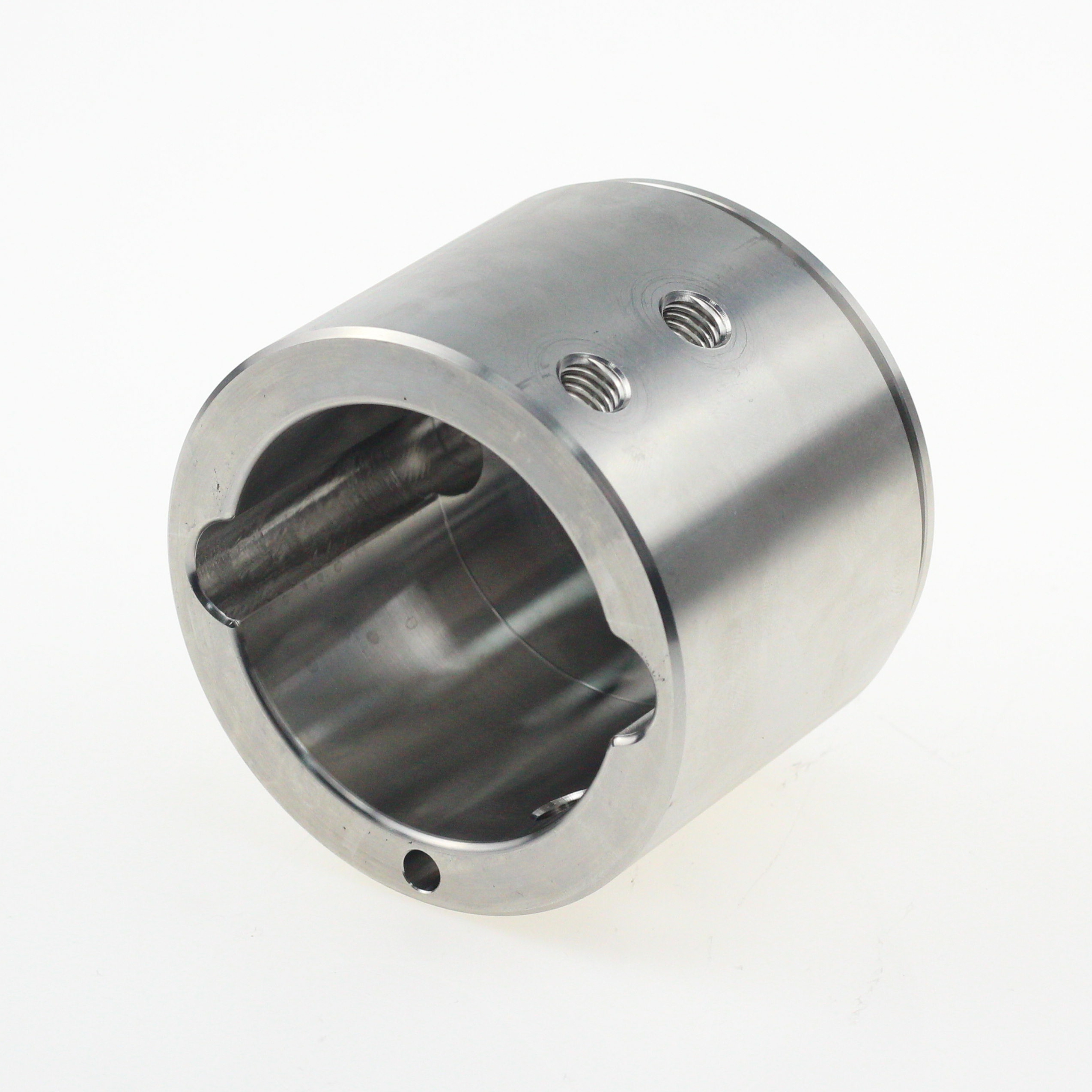

The customer needs a highly wear-resistant and high-strength metal bushing for their transmission system and robotic arm joint parts. These metal bushings need to have excellent corrosion resistance, high temperature resistance, and high dimensional accuracy. Due to the strict requirements of the customer's products, they are very strict with the supplier's technical capabilities and production standards.

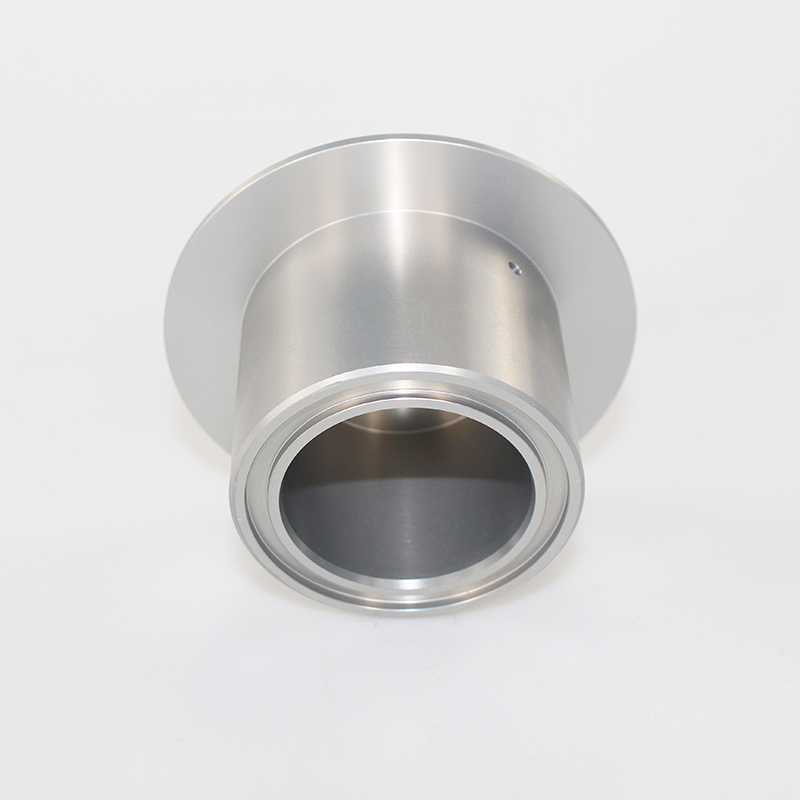

According to the customer's requirements, we recommend the use of high-alloy steel (such as stainless steel or alloy steel) with excellent wear resistance and corrosion resistance. These materials can ensure that the bushing works stably under high load and high temperature environments and has a long service life. We use advanced CNC lathes and precision milling equipment for processing to ensure that the dimensional tolerance and surface roughness of each metal bushing meet customer requirements. In particular, we have carried out fine grinding on the inner and outer surfaces of the bushing to ensure accuracy and finish and avoid damage caused by friction.

Each batch of bushings produced undergoes rigorous quality inspections, including dimensional inspection, hardness testing, corrosion resistance testing, etc., to ensure that the products meet customer standards. We use a three-coordinate measuring machine to accurately measure each bushing to ensure that all parts meet international quality certifications. Since the customer is located in the United States, we provide professional packaging solutions to prevent damage during transportation. Each bushing is packaged with a customized foam liner and waterproof and moisture-proof packaging, and a final inspection is performed before shipping.

Through close cooperation with the customer, we have successfully produced high-quality metal bushings for it, fully meeting its application needs. The customer expressed high satisfaction with the product quality and delivery efficiency we provided, and expressed that he would continue to work with us. Due to the excellent performance of the product, the customer further expanded the order volume and plans to list us as a long-term partner.