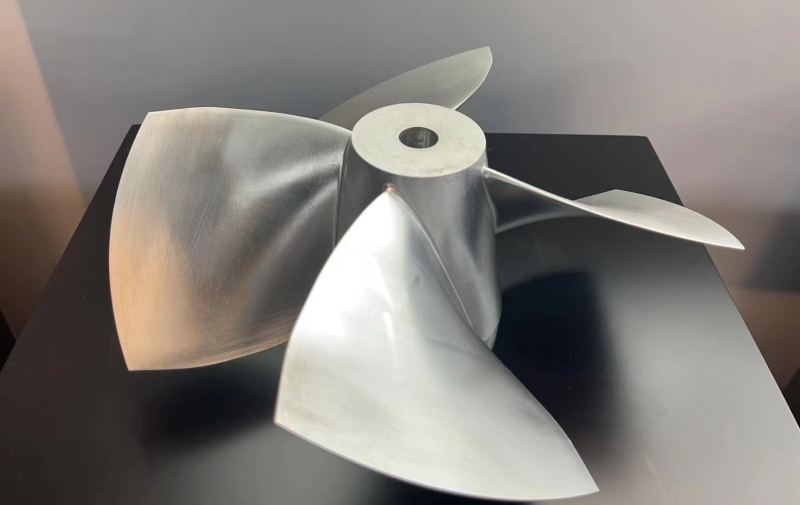

After being introduced by a Japanese customer we had cooperated with before, we successfully reached cooperation with a pump and valve manufacturing company. The customer's main goal was to ensure that the dimensions and tolerances of the impeller met industry standards and that high-quality materials were used to improve the impeller's corrosion and wear resistance. On the premise of ensuring quality, the production cycle is shortened to respond to market demand.

In the early stage, KAIYE conducted detailed technical communication with the customer to clarify the design requirements, material specifications and expected production volume of the impeller. An initial sample was produced based on the customer's design drawings. After the sample was completed, both parties conducted tests to evaluate its performance and durability. During the testing phase, customers made suggestions for improving the samples, and our company made several adjustments based on the feedback and made new samples again.

After a long period of modifying the trial mold, the sample passed the test and was finally put into mass production. During the production process, our company's strict quality control process includes regular inspections and tests to ensure that the quality of each batch of products meets standards.

According to customer feedback, the dimensional tolerance of the impeller is within ±0.01mm, which significantly improves the consistency and reliability of the product. Production has been optimized, further enhancing their competitiveness in the market.

We are very grateful to our old customers for supporting us and recommending new customers. We are also very grateful to new customers for their trust and cooperation in us.