Over the past few years, CNC machining technology has evolved from simple machine tools to more complex machine tools. 5-axis CNC machining is one of the most advanced machining processes available today, and it has advantages and disadvantages.

Advantages of 5-axis machining

Machining complex shapes

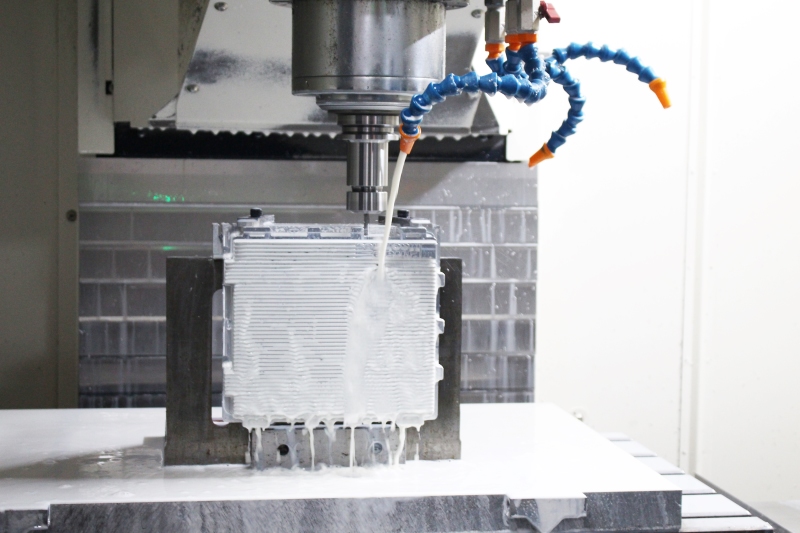

The extra rotation in this machining process helps achieve more complex designs and geometries. The machine can seamlessly machine arcs and angles that were previously only possible with multiple special fixtures. The 5-axis milling process can rotate parts to achieve the desired geometry in a single operation without the need for complex fixtures. Additionally, this technology pairs perfectly with GD&T annotation to generate datum features in a single operation. 5-axis milling is also suitable for CNC machining applications that require surface profile tolerances on complex contoured surfaces.

High precision

Compared to CNC machining, the extra setup involved with manual machining can cause machinists to lose precise alignment during the manufacturing process. However, the minimal setup involved in 5-axis CNC milling reduces the possibility of errors and increases machining accuracy. Through 5-axis machining technology, the problem of multiple repositioning accuracy of workpieces at complex angles is solved. It not only shortens the time, but also greatly improves the machining tolerance many times.

Reduce processing time

In 5-axis machining, the tool is used to maintain the vertical state of the complex mold processing surface, which can greatly improve the spindle utilization rate. The 5-axis machining principle is also suitable for bevel side milling, which can eliminate the rib-like patterns caused by ball cutters. This results in a better surface quality of the mold and reduces the manual work required to clean the mold surface. 5-axis machining of parts is typically done in one operation because of the high speed of the process. The single setup involved helps save time and money. Additionally, shorter tools last longer, eliminating the need for constant tool replacement, saving money and time.

Disadvantages of 5-axis machining

High initial cost

The cost of purchasing a 5-axis CNC machine and its basic software is high. It is much higher than what is needed for a 3-axis machining center. Likewise, the machine's maintenance requirements are more challenging than with traditional machine tools. This aspect also directly increases the processing cost of 5-axis machined parts.

Programming is difficult

Since 5-axis machining is different from 3-axis, in addition to three linear motions, it also involves two rotational motions. The resulting spatial trajectory of the synthetic motion is very complex and abstract, and is generally difficult to imagine and understand. For example, in order to process the required spatial free-form surface, it is often necessary to undergo multiple coordinate transformations and complex spatial geometric operations. It is also necessary to consider the coordination of the motion of each axis to avoid interference, collision, appropriate interpolation motion, etc. To ensure the required machining accuracy and surface quality, programming is even more difficult.

Higher requirements on operators

5-axis CNC milling is an advanced technology that involves advanced programming, machine setup, and operation. Therefore, the process requires highly skilled technical operators. This usually means increased labor costs.