Integrated die-casting realizes the one-time molding of multiple parts through integrated manufacturing, which makes up for the many shortcomings of aluminum alloy structural parts in traditional automobile production processes. It is an excellent choice for future automobiles to increase the amount of aluminum used and pursue lightweighting. At present, the integrated die-casting process is helping aluminum alloy bodies penetrate into mid- to low-end models, and the market space is expected to make further breakthroughs.

Advantages of integrated die casting

Production costs fall

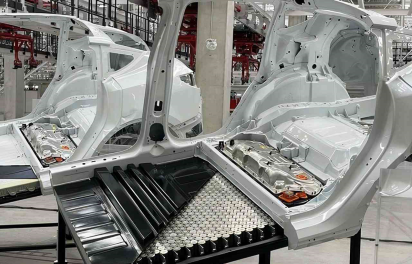

Reduced production line costs: Under the traditional "stamping and welding" process, the body-in-white assembly requires hundreds of parts that need to be processed separately, requiring a large number of stamping machines, molds, welding fixtures, inspection machines and other equipment to support a complete production line Large scale and high cost. In contrast, the integrated die-casting process will significantly reduce the number of parts that need to be prepared. The preparation of the entire body-in-white is only achieved through 3-5 large die-casting machines, a small number of auxiliary machines and molds, and the construction of the production line Costs dropped significantly. In addition, with the same production capacity, the integrated die-casting production line saves factory space.

Reduce material costs: During the stamping process, scraps will inevitably be produced after the raw materials are extruded. However, the liquid metal injected during integrated die-casting is equivalent to the casting material at a ratio of one to one, and the material utilization rate is higher. In addition, traditional car bodies use complex materials, and different parts usually correspond to different types and material models. After recycling, they can only be used for raw material production, with a recycling rate of about 70%. However, integrated die-casting parts only use a single aluminum alloy, and the car body can be recycled It is directly melted and remade, with a recycling rate of over 95%. The weight of the aluminum alloy body under integrated die-casting is about 200-250kg. It is expected that the weight of the traditional steel-aluminum hybrid body of the same level is about 280kg. Although the unit price of aluminum alloy materials is higher than that of steel, considering that the materials used for the integrated all-aluminum body are more expensive Less, and with the advantages of material utilization and recycling rate, the full-cycle comprehensive material cost of the integrated aluminum alloy body will be lower than the traditional "stamping and welding" process all-aluminum body and most steel-aluminum hybrid body.

Reduce labor costs: Under integrated die-casting, the welding points of the car body are greatly reduced, and the demand for welding technical workers decreases. At present, domestic mainstream welding factories are usually equipped with 200-300 workers. After adopting integrated die-casting technology, the required skilled workers can be reduced to at least one-tenth of the original number.

Improve production efficiency

Reduce stamping, welding and heat treatment workload: In traditional car body manufacturing, more than 500 types of parts need to be manufactured separately, involving many stamping and welding processes. However, integrated die-casting technology greatly simplifies this and significantly reduces the workload.

Eliminates a large number of glue coating processes: In traditional automobile manufacturing, there are gaps between spot welded steel plates, and the glue coating process is required to achieve sealing and waterproofing, increase the strength of the car body, and reduce friction and vibration between sheet metal parts. After changing to a one-piece die-cast car body, the parts are assembled into an assembly after being formed. The cumbersome glue application process is no longer needed, and the production process is simplified again.

The model development cycle is shortened: In traditional car body manufacturing, in order to achieve precise solidification of parts, they usually need to go through three rounds of matching and debugging, MB1, MB2, and MB3, which takes nearly 6 months in total. However, integrated die-casting technology relies on the large number of parts. The reduction can shorten the cycle required for car body matching in MB to 1-2 rounds, saving 3-4 months of matching time.

High accuracy of car making

Integrated die-casting technology can shorten the size chain for body matching to 2 to 3 links. The fewer size links, the fewer factors that affect the body accuracy, and the more controllable the body accuracy is. It is expected that with the support of CNC processing technology, the accuracy of the die-cast body can reach the micron level. In the field of autonomous driving, vehicles need to detect and perceive road conditions through high-precision measuring instruments such as lidar, millimeter-wave radar, and high-definition cameras. To ensure the accuracy of measurements, the yaw angle, pitch angle, and roll angle of the measuring instruments are all equal. Need to be strictly controlled. The high-precision advantage of integrated die-casting technology can minimize the impact of the body on the installation of measuring instruments, which is beneficial to the development of autonomous driving technology.

High security

Integrated die-casting technology replaces the welding process with die-casting, which avoids the problem of strength reduction in the heat-affected zone that is prone to aluminum alloy welding and improves the connection strength. In addition, there is no need to consider the size and position of the mounting holes when designing integrated die-casting parts, making it easier to achieve an optimal engineering structure, thereby giving the body greater impact resistance.

Lightweight advantage

According to a car review data, the traditional steel body weighs 350kg-450kg, while the raw material of the integrated die-cast body is aluminum alloy, and the body weight is about 200-250kg, which has the advantage of being lightweight.

Disadvantages of integrated die casting

High equipment input cost

The purchase price of a heavy-duty die-casting machine often costs hundreds of millions, while a traditional stamping machine only costs tens of millions of yuan; the life of a stamping mold can reach 500,000 times, while a die-casting mold can only be used more than 80,000 times.

High material and process requirements

Traditional die-casting aluminum alloy die-casting parts require solid solution and aging heat treatment to meet the strength, durability, and impact resistance required for vehicle body performance. During the heat treatment process, die-casting parts are prone to dimensional deformation and surface defects. Since traditional die-casting parts can cause problems such as surface collapse and cracks during heat treatment, one-piece die-cast body structural parts require aluminum alloys as raw materials that are both strong and ductile and do not require heat treatment to avoid deformation. The research and development of new materials requires a large number of basic scientific experiments as support. The layout of the die-casting cooling water, the settings of peripheral machines, and the pressure parameters used are accumulated through years of project experience. Therefore, if you want to ensure a high product yield, you need years of experience in die-casting parameters.

High damage repair costs

Body repair costs are high, and damage requires complete replacement.