As a key technology for creating high-performance graphics processor, graphics card die-casting process plays an important role in the field of graphics processor manufacturing. This article will introduce its advantages and key points to pay attention to.

Advantages

Low cost

Compared with traditional manufacturing processes, graphics card die-casting process has significant cost advantages. Through one-time molding, there is no need for multiple processing steps, which reduces the cost of graphics card manufacturing. Moreover, the investment in die-casting equipment is relatively low, which not only saves production costs but also improves the competitiveness of enterprises.

High efficiency

The high efficiency of graphics card die-casting process is also amazing. During the die-casting process, it only takes a few minutes to complete the molding of a part, which greatly saves time. Moreover, compared with other processes, the energy required for die-casting is relatively less, which is beneficial to energy conservation and emission reduction.

Strong stability

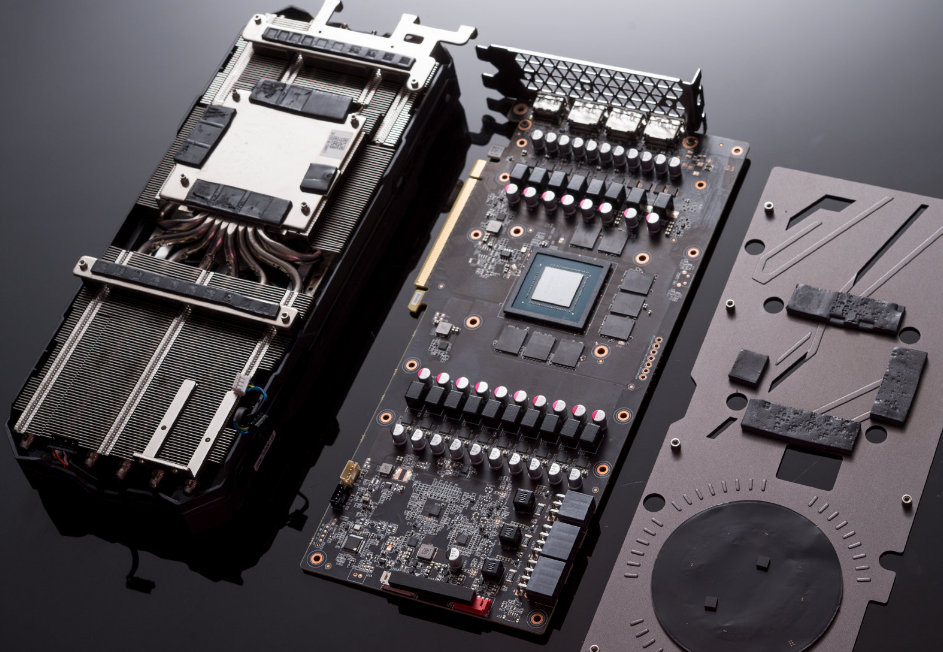

As the core component of the graphics processor, stability naturally becomes an important indicator. The characteristics of the die-casting process determine that the structure of the graphics card is more compact, reducing the gap between parts, thereby improving stability. In addition, the die-casting process can also ensure the uniformity of the material and enhance the durability and impact resistance of the graphics card.

Key points

Material selection

The materials used in the graphics card die-casting process are often metal materials with high thermal conductivity, high strength and corrosion resistance, such as aluminum alloy or magnesium alloy. These materials have good thermal conductivity, can effectively dissipate heat and ensure the stability of the graphics card. In addition, high strength and corrosion resistance can ensure the service life and stability of the graphics card.

Design optimization

In the graphics card die-casting process, design optimization is a key link to improve the performance of the graphics processor. Through reasonable design, the defects and defects that occur in the die-casting process can be reduced to ensure the integrity and stability of the parts. In addition, the performance of the graphics processor can be improved by optimizing the structure, increasing the surface area and heat dissipation performance of the parts.

Process control

In the graphics card die-casting process, process control is also a crucial link. Through reasonable process parameter selection and strict process control, the molding quality of graphics card parts can be guaranteed. For example, during the cooling process of the casting, the cooling rate is reasonably controlled to avoid problems such as cracks and deformation. In addition, regular maintenance and maintenance of the die-casting equipment is required to ensure the operating stability of the equipment.