With the surge in global demand for sustainable energy, the new energy industry, especially the rapid development of battery technology, is becoming the focus of attention of various industries. In this green revolution, high-precision machining technology of battery components plays a vital role, not only ensuring the reliability of battery performance, but also providing key support for promoting the widespread application of electric vehicles, energy storage systems and other new energy products.

In recent years, with the continuous advancement of technologies such as lithium batteries and solid-state batteries, the production process of batteries has also ushered in a revolutionary change. Especially in the machining of battery components, high-precision processing equipment and technology are widely used in the manufacture of core components such as battery casings, connectors, end caps, and conductive joints. These components play a key role in the overall performance, life and safety of the battery, so the requirements for their machining accuracy are very high.

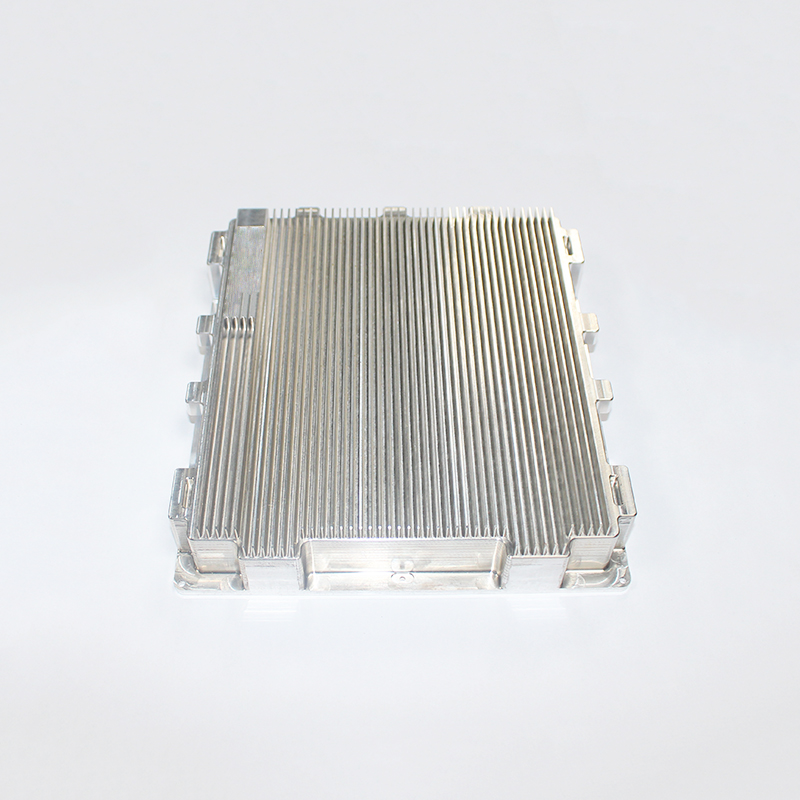

The machining process of battery components usually includes milling, drilling, turning, laser cutting, welding and other steps. Taking the shell of lithium batteries as an example, these shells not only need to have strength, sealing and good heat dissipation performance, but also need to be able to withstand certain pressure and temperature changes. In order to meet these requirements, the machining accuracy of the battery shell is crucial. Any slight error may lead to unstable battery performance and even bring safety hazards.

High-precision machining equipment, such as CNC lathes, CNC milling machines, and laser cutting machines, can ensure the size and shape of parts at the micron level. The application of these technologies not only improves production efficiency, but also greatly reduces the scrap rate that may occur during the production process.

The machining technology of battery components is not only the foundation for the development of the new energy industry, but also an important force in promoting the global green energy transformation. From high-precision machining to intelligent production, the continuous innovation and application of these technologies are providing a solid guarantee for the popularization and application of new energy products. With the continuous advancement of technology, the machining of battery components will usher in a broader prospect in the future and make greater contributions to the optimization of the global energy structure.