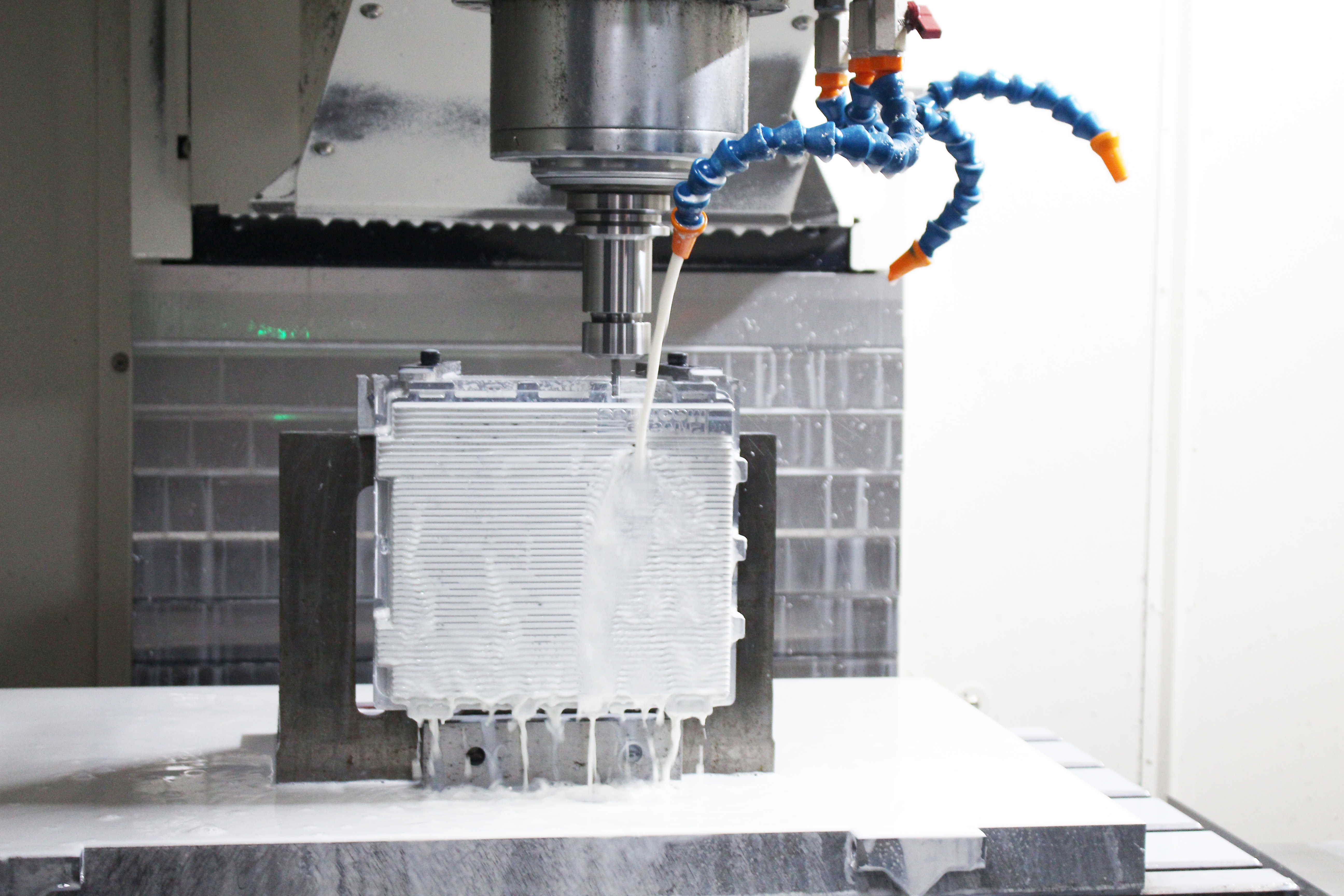

CNC machine is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions and decode them to make the machine move and process parts. Compared with ordinary machine, CNC machine have the following characteristics: high processing accuracy and stable processing quality; they can perform multi-coordinate linkage and can process parts with complex shapes; when processing parts change, generally only the CNC program needs to be changed, which can save production preparation time; the machine itself has high precision and rigidity, and can choose favorable processing amounts, and has high productivity (generally 3 to 5 times that of ordinary machine tool); the machine has a high degree of automation, which can reduce labor intensity; and the quality requirements for operators are higher, the technical requirements for maintenance personnel also are higher.

In terms of composition, CNC machine are mainly divided into three parts: the machine body, the transmission system and the CNC system.

Machine body

The main body of CNC machine is the main component of the machine and the hardware of machine. It is an important mechanical accessory part of CNC machine and the most easily visible part with the naked eye, including machine bed and base castings, spindle and gearbox, guide rails and slides, lubrication, chip removal and cooling parts.

Transmission system

The transmission system is an important part of the CNC machine. It guides the orderly progress of all parts of the machine and completes the work mission of machine It includes cutting tools, transmission machinery and auxiliary power systems. As far as the tool part is concerned, it includes protection devices, tool magazines and tool changing devices; the transmission machinery, as the second largest component of the transmission system, includes three parts: ball screws, linear guides and worm pairs; the auxiliary power system includes hydraulic systems and Start the two parts of the system, which are the power of the CNC machine.

CNC system

The CNC system can be said to be the soul of the CNC machine tool and the essence of the machine tool's various functions and operations. CNC systems are basically divided into two categories, driving devices and control and detection devices. Driving devices include high-speed spindles, torque motors, linear motors, ordinary motors and stepper motors; control and detection devices include CNC systems, programmable controllers, feed servo control modules, position detection modules, etc.