CNC machining of robot arm parts is a high-precision and high-efficiency machining method. With the progress of society, the use of advanced technology can effectively compete in the industry. One of the mechanical equipment used in automation, CNC robot arms, is revolutionizing the manufacturing industry, especially 6-axis robot arms. CNC robot arms combine precision and adaptability, and are designed to complete complex tasks with optimal precision and efficiency. Compared with existing organizational workflows, the use of these robot systems can shorten production cycles, reduce the degree of human error, and increase production capacity.

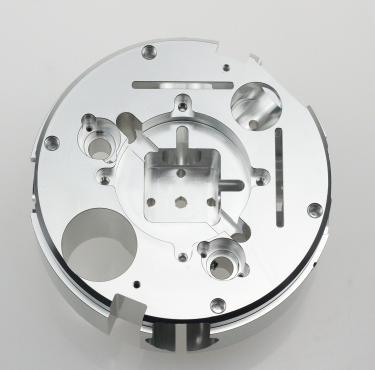

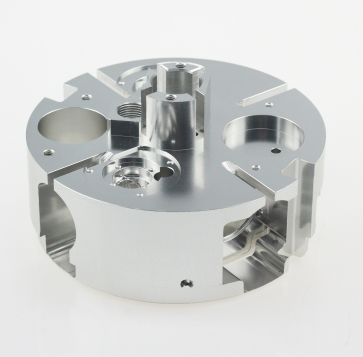

The parts of the robot arm that need to be machined include but are not limited to:

Joint parts: including joints that connect the various parts of the arm, which need to be precisely machined to ensure flexible movement and stability.

Transmission parts: such as reducers, gears, etc., used to transmit power and control the movement of the arm.

Structural parts: such as brackets, connecting plates, etc., used to support and connect the various parts of the arm.

Gripping parts: fixtures, grippers, etc., used to grab and manipulate objects.

Sensor parts: such as encoders, sensors, etc., used to sense the surrounding ring and feedback the position and state of the arm.

Control components: such as motors, servo drives, etc., used to control the movement of the arm and perform tasks.

Different types of robot arms may have some special parts and structural designs to meet different application requirements. Through CNC machining, high-precision machining of robot arm parts can be achieved, production efficiency can be improved, and product quality can be ensured. At the same time, CNC machining can also realize automated production, reduce manual intervention, and reduce production costs. Therefore, CNC machining plays an important role in the manufacturing of robot arm parts.