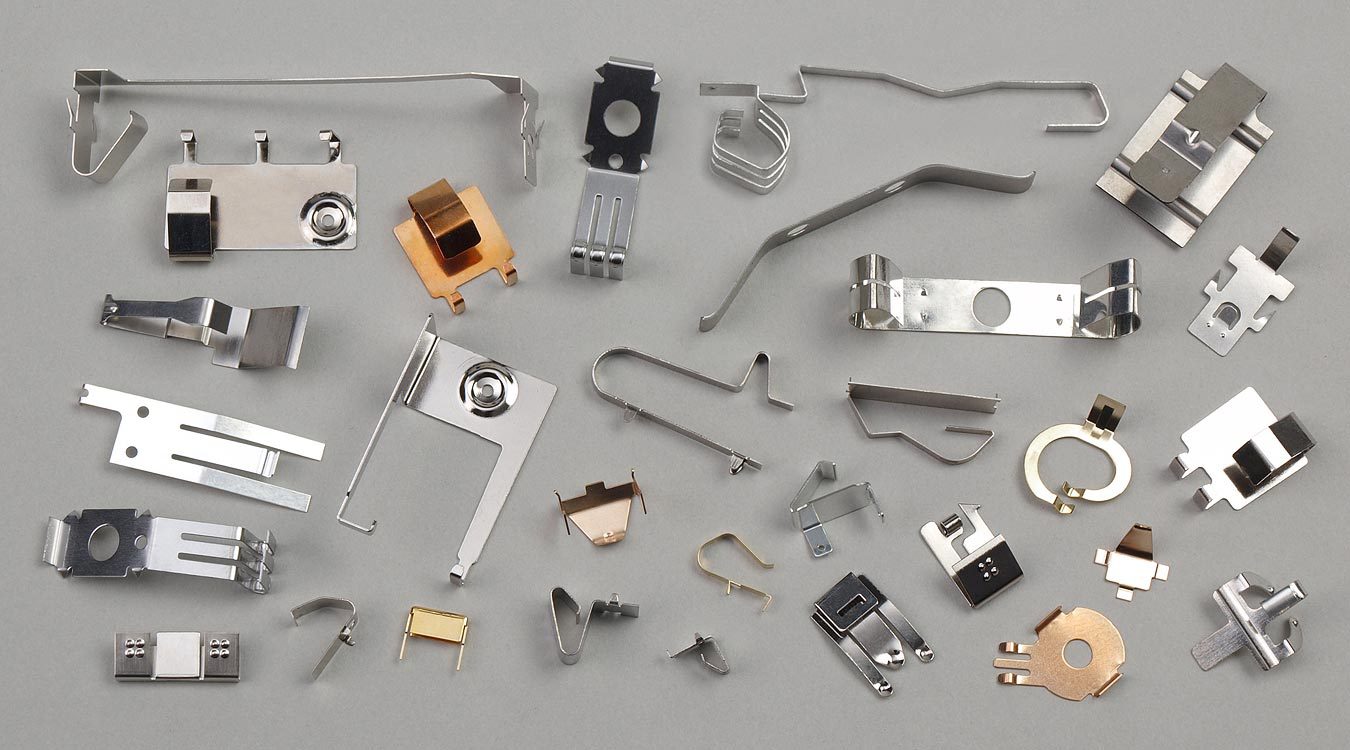

Contact sheet stampings are metal parts widely used in electronic equipment and electrical connections, mainly used to achieve electrical contact. They are used in home appliances such as power sockets and switches; in automobiles for connectors, sensors and other components; and in electronic equipment such as mobile phones and computers for internal connections.

Copper is a common material with excellent conductivity. Brass is corrosion-resistant and suitable for long-term use. Tin plating or nickel plating can improve oxidation resistance and extend service life. High conductivity can effectively transmit current, reduce power consumption and heat generation. Good elasticity can maintain contact force and ensure reliable connection. Good wear resistance, suitable for frequent plugging and unplugging.

With the rapid development of emerging industries such as smart homes and electric vehicles, the demand for contact sheets is also increasing, and many companies have begun to expand their production capacity to meet market demand. Many companies continue to innovate in contact sheet materials and manufacturing processes, such as developing new alloy materials or using advanced stamping technology to improve conductivity and durability. As global environmental protection requirements increase, contact sheet manufacturers are facing increasingly stringent environmental regulations, which has prompted them to look for more environmentally friendly materials and production methods.