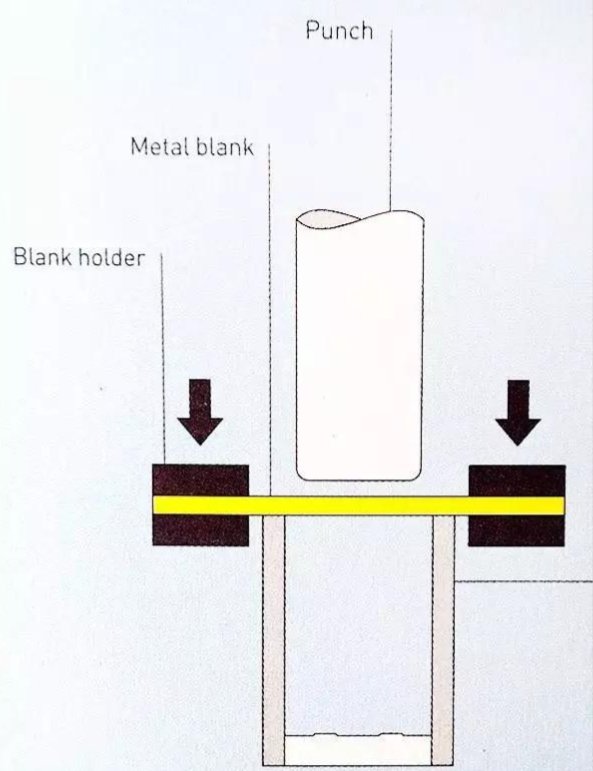

Metal deep drawing is a process of stamping metal sheets into hollow cylinders and is suitable for producing parts and components of various shapes. It places a metal plate or metal blank in a mold, and uses the stretching effect of the mold to plastically deform the metal material, and finally obtains the required formed parts. Deep drawing technology is widely used in production processes, such as the production of automobile parts; it can also be used to manufacture household products, such as stainless steel kitchen sinks.

The deep drawing process relies on the balance of metal ductility and compression resistance. Suitable metals are: steel, copper, zinc, and aluminum alloys. Other metals are prone to tearing and wrinkling during the deep drawing process. Because the ductility of metal directly affects the production efficiency and quality of deep drawing, metal sheets are generally used as raw materials for processing.

The main process of deep drawing molding process includes planning, mold design, material selection, molding, trimming and other steps.

Planning: Before deep drawing molding, the product needs to be planned first. The planning stage includes determining the shape, size, material requirements, etc. of the product. During the planning stage, factors such as the product’s functional requirements, assembly requirements, and production costs need to be taken into consideration.

Mold design: Mold design is an important step in the deep drawing molding process. The goal of mold design is to design a suitable mold according to the shape and size requirements of the product. Mold design needs to take into account factors such as the shape and structure of the product, the direction of material discharge, and the size of the material. Reasonable mold design can improve molding efficiency and product quality.

Material selection: During the deep drawing molding process, material selection directly affects the performance and quality of the product. Choose the appropriate metal material according to the characteristics and requirements of the product. Commonly used metal materials include cold-rolled steel plates, stainless steel plates, aluminum alloys and other materials. The selection of materials needs to take into account factors such as the mechanical properties, cost and processability of the materials.

Forming: Forming is the core step of the deep drawing forming process. During the forming process, a metal sheet or blank is first placed in a mold. Then through the action of mechanical force, the metal material is stretched and gradually deformed to achieve the desired shape and size. During the molding process, parameters such as molding speed, molding strength, and temperature need to be controlled to ensure the quality of molded parts.

Trimming: After the molding is completed, trimming is required. Trimming mainly involves deburring, puncture marks, and trimming of molded parts. During the trimming process, manual trimming or mechanical trimming can be used to obtain flat and smooth molded parts.