Hot stamping is a part processing method that first heats the blank to a certain temperature, and then uses a stamping machine to stamp and hold pressure quenching in the corresponding mold to obtain the required shape and achieve phase change of the metal material at the same time.

Hot stamping technology is to heat the boron steel plate (initial strength is 500~700MPa) to the austenitized state, and quickly transfer it to the mold for high-speed stamping forming. Under the condition of ensuring a certain pressure, the parts are formed in the mold body at quenching and is performed at a cooling rate greater than 27°C/s, the pressure is maintained for a period of time to obtain the forming method of ultra-high-strength steel parts with a uniform martensite structure.

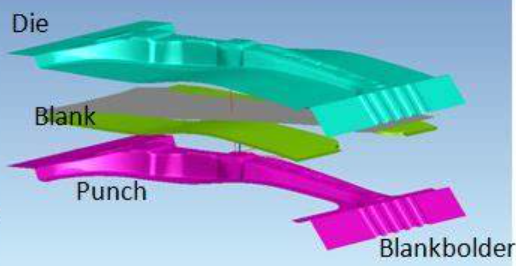

Hot stamping technology is divided into two types: direct hot forming and indirect hot forming. The direct hot forming method is to heat the sheet material, shape it and then quench it, while the indirect hot forming method is to preform the sheet material first, then heat it, form it and then quench it.

Advantages of hot stamping: Ultra-high strength body parts are obtained; the weight of the body can be reduced; the safety and comfort of the body can be improved; the stamping formability can be improved; the dimensional accuracy of the parts can be improved; the surface hardness and dent resistance can be improved and corrosion resistance; reducing the tonnage requirements of the stamping machine.