With the rapid advancement of information technology, the CNC machining industry in automotive parts manufacturing is undergoing a profound digital transformation. Here are the key innovative technologies and specific applications in CNC machining of automotive parts.

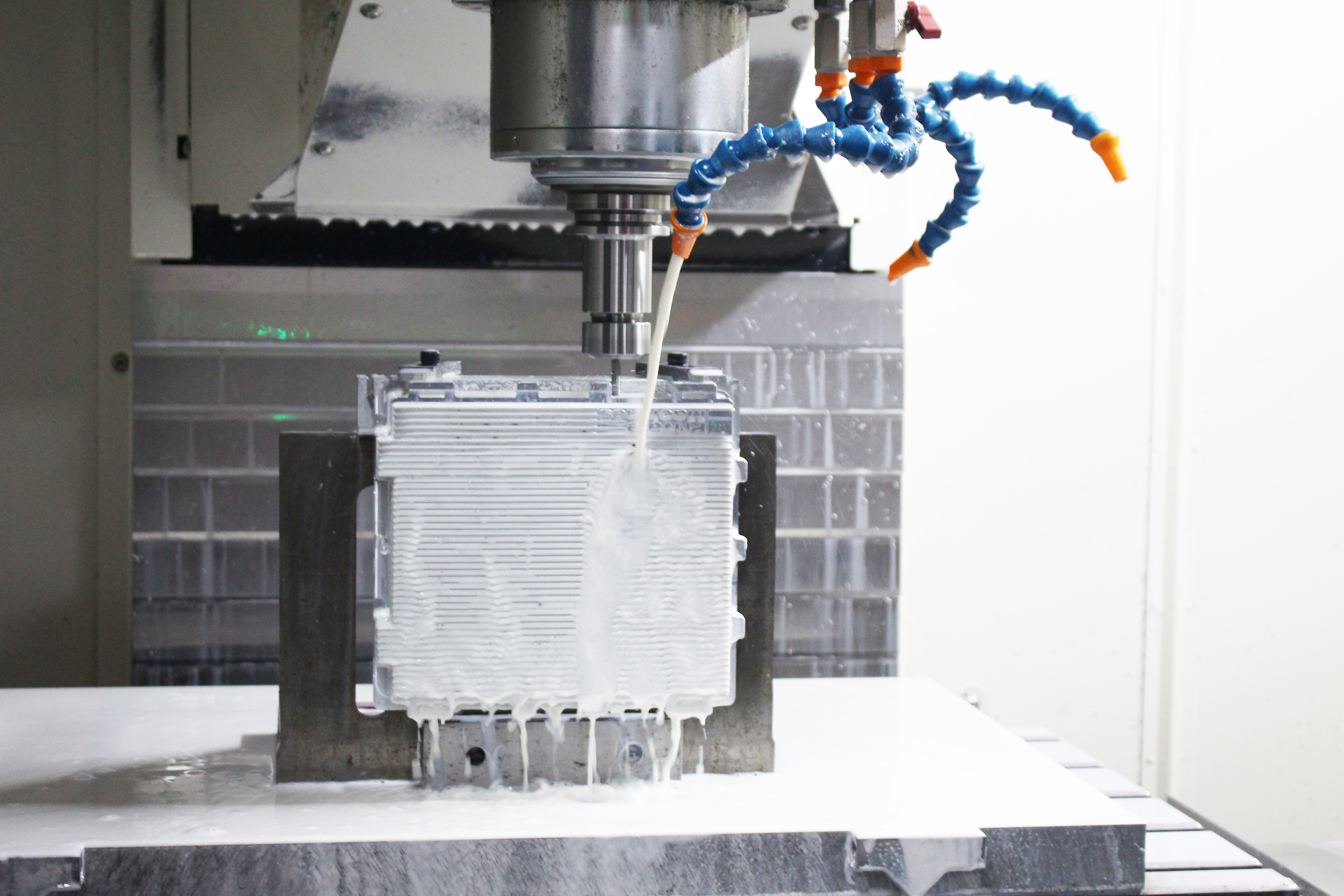

High-Precision Five-Axis Machining Technology

Five-axis machining technology enables complex machining of components across multiple axes, significantly enhancing machining precision and surface quality. This technology is crucial in manufacturing critical automotive parts such as engine and transmission systems. By controlling multiple axes simultaneously, five-axis machining reduces machining steps and cycle times, avoids cumulative errors from multiple setups, and improves assembly accuracy and reliability.

Intelligent Tool Management Systems

Intelligent tool management systems utilize RFID technology and internet connectivity to monitor and manage real-time tool life, wear status, and usage conditions. These systems automatically adjust tool usage frequency and replacement times based on actual machining conditions, effectively extending tool life and reducing production downtime. In large-scale automotive parts production, intelligent tool management systems enhance production efficiency, lower manufacturing costs, and reduce energy consumption.

Virtual Simulation and Digital Twin Technology

Virtual simulation and digital twin technology provide new means for process optimization and quality control in CNC machining of automotive parts. By establishing digital twin models and virtual simulation environments, manufacturing companies can simulate and optimize the entire machining process on computers, including cutting parameter selection, machining path planning, and process flow design. This technology not only predicts and prevents potential machining issues but also monitors and adjusts the machining process in real-time to ensure final part accuracy and quality meet design requirements.

Personalized Customization Solutions

With increasing consumer demand for personalized automotive configurations, CNC machining technology is evolving towards customized solutions. Through flexible programming and advanced machining equipment, manufacturing companies can quickly respond to market demands and produce customized parts that meet specific customer requirements. This capability enhances market competitiveness and provides automotive manufacturers with innovative and differentiated sales strategies.

Environmentally Friendly Manufacturing Technologies

As global environmental concerns escalate, the automotive parts manufacturing industry is actively exploring sustainable development paths. The application of next-generation energy-efficient CNC equipment, eco-friendly materials, smart energy management, and optimized production processes helps reduce carbon emissions and resource consumption, driving the industry towards more environmentally friendly and sustainable practices.

Overall, CNC machining technology's extensive application in automotive parts manufacturing has significantly boosted efficiency and technological advancements in the industry. With continuous innovation and expanding application scenarios, the future is expected to further propel the automotive industry towards higher quality, more intelligent, and sustainable development.