Precision parts machining is a key technology in the manufacturing industry, involving high-precision machining of parts to meet strict dimensional tolerances and surface finish requirements. This machining method is widely used in industries such as aerospace, automotive, medical equipment, and electronics.

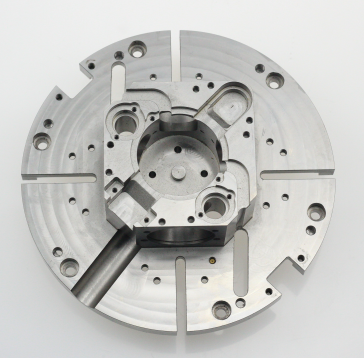

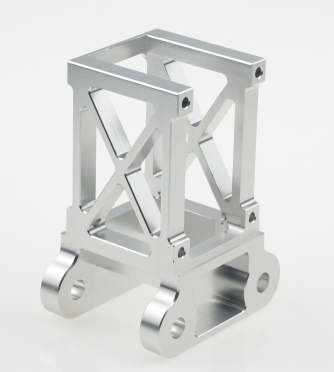

The parts are high-precision and complex in shape, usually requiring tolerances of ±0.01mm or less to meet strict design specifications. Complex geometries can be machined, including holes, slots, curved surfaces, etc. A variety of machining methods are required, including milling, turning, grinding, and electrical discharge machining (EDM), etc., to adapt to different materials and requirements. Computer numerical control machine tools can accurately control the movement of the tool and are suitable for mass production and complex shape machining. Grinding can improve surface finish and dimensional accuracy and is suitable for materials with higher hardness. EDM is suitable for difficult-to-machine materials and can achieve high-precision holes and complex shapes.

Precision parts are often used in aerospace to manufacture engine components, structural parts, etc., requiring extremely high strength and precision. In the medical device field, surgical instruments, implants, etc. are produced, which must meet strict biocompatibility and precision standards. In the automotive industry, engine parts, gearbox parts, etc. are manufactured to ensure their performance and safety. For electronic products, tiny parts such as connectors and radiators are processed to meet electrical performance and heat dissipation requirements.

In general, precision parts machining is an indispensable part of modern manufacturing and is of great significance to improving product performance and market competitiveness.