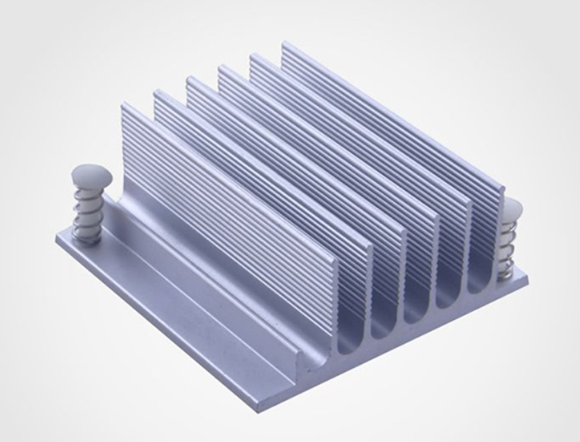

The design and processing of radiators must ensure good heat dissipation performance, which is common in electronic equipment, automobile engines and other fields that require heat dissipation. Radiators can indeed be manufactured through die casting, especially aluminum radiators, which can effectively produce parts with complex shapes and high precision. But radiators can also be manufactured using sheet metal processing technology, especially for some applications with specific design or size requirements.

Die casting can achieve complex shapes and high precision parts. The surface after molding is smooth, reducing subsequent processing. Suitable for mass production and reducing unit cost. However, the initial mold cost is high, which is suitable for large-scale production. It is usually suitable for casting alloys such as aluminum and zinc, and the material selection is limited. The process of melting metal consumes a lot of energy.

Sheet metal processing cuts metal sheets into the required shape and size, bends the metal sheets into specific angles through a bending machine to form the shell or channel of the radiator, welds different metal parts together to form a complete radiator structure, and performs spraying, anodizing and other treatments to improve the corrosion resistance and aesthetics of the radiator. The design can be quickly adjusted as needed, which is suitable for small batch production. A variety of metal materials such as steel, aluminum, stainless steel, etc. can be used. For small batches or diversified products, the initial cost is low. However, for complex shapes, more post-processing may be required. Compared with die casting, mass production is less efficient. Sheet metal parts usually require spraying or other surface treatments to improve corrosion resistance.

In general, the production of radiators requires the selection of appropriate processes based on project requirements and production scale.