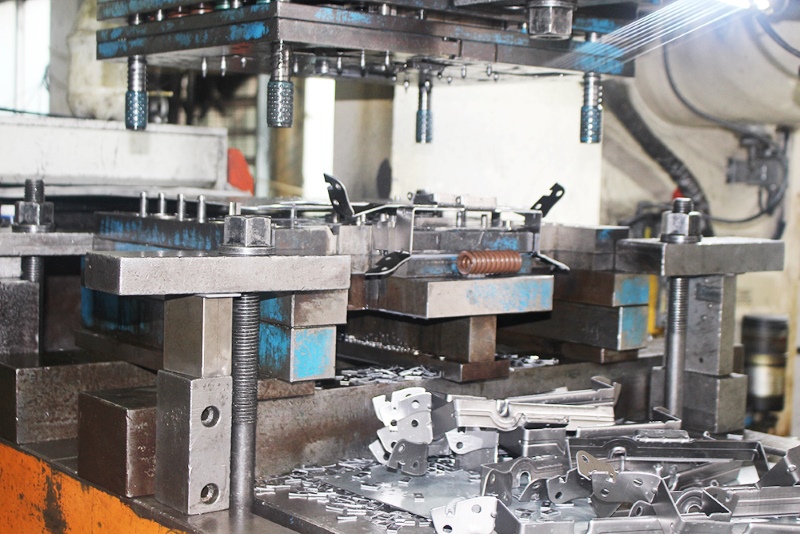

Depending on the shape of the part or product, metal stamping involves a variety of different processes, each one different. These processes are used to achieve complex and detailed designs of parts and products. It is usually not possible to use a metal stamping method to make a part because each process involves making a specific design.

Perforation

Perforation is one of the most basic forms of metal stamping. In this method, the sheet metal is placed securely on the workbench. Use a machining tool to punch holes in the metal plate to create multiple small hollow areas. Unlike other technologies, the punched material produced during the entire machining process is discarded and not used later. In this type of process it is important that the punching motion remains instantaneous. This ensures that no deformation occurs in the area around the hole. Piercers are usually made of high carbon steel and kept in good condition to avoid deformation of the shape of the metal workpiece.

Blanking

Blanking looks similar to punching, but there is one major difference, punched pieces are not discarded but are considered finished products. Many metal stampers typically do this as the first stage of the overall metal stamping project, followed by other techniques such as piercing, bending or stamping. Blanking is used to process small or medium-sized pieces of metal cut from large sheets of metal. However, in some cases, the cut metal product may have burrs or sharp excess edges. Although they are common, they are usually removed by manual deburring, vibrating the finish, or thermal deburring.

Stretching

Use a machine to secure the ends of the sheet metal together. Underneath the sheet metal is a mold with a certain shape or cross-section. The punch creates a high-impact force that pushes the metal plate against the mold, effectively deforming it to match the cross-section of the mold.

Forging

Forging is a metal stamping technique in which a small piece of metal is stamped into the shape and features of a coin. This is a closed die forging technique in which the whole or part of a metal sample is stamped by two dies approaching each other on either side of the metal.

Piercing

Unlike piercing and blanking, piercing is a type of metal stamping that does not remove metal parts. Instead, the way dies and punches work is that they both create a crack in the sheet of metal. This process does not create scrap iron pieces that must be discarded or removed during post-processing.

Embossing

Embossing is a technique that creates a unique raised surface on a sheet of metal. Embossed materials can be produced in two ways, by using machines or die sets. Mainly used to create parts and assemblies for a variety of different applications, depending on the complexity of the design required and its form.