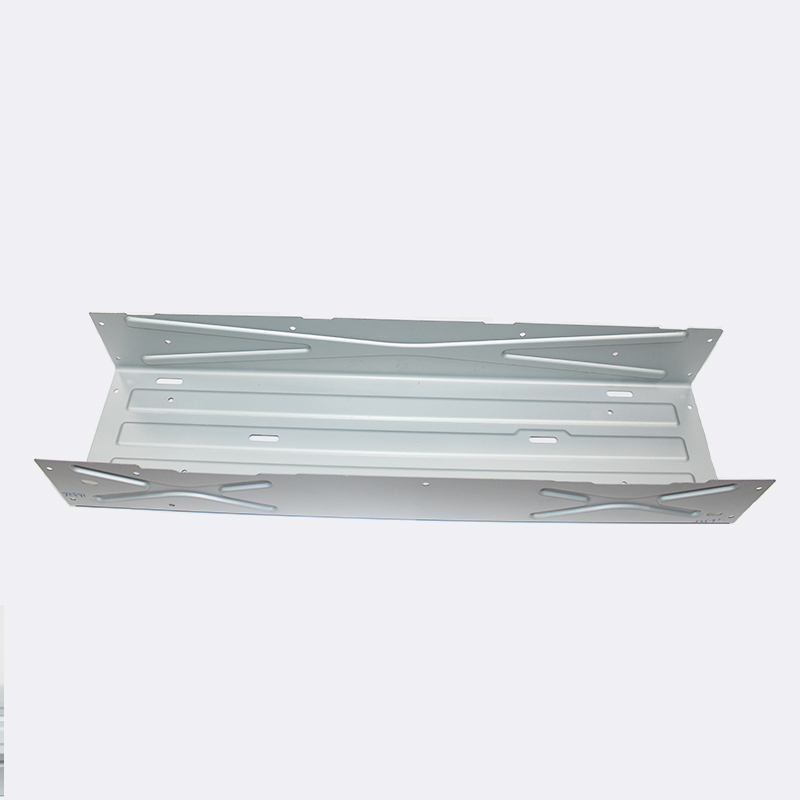

Sheet metal stamping rail brackets are commonly used to support and fix rail systems and are widely used in mechanical equipment, automation equipment, and electronic equipment.

First, use CAD software to design the bracket to ensure that it meets the functional and strength requirements. Common materials include cold-rolled steel, galvanized steel, or stainless steel, which are selected according to corrosion resistance and strength requirements. Use a stamping machine for forming to quickly and efficiently cut and form parts. Surface treatments such as spraying, galvanizing, or oxidation can be performed to improve durability and aesthetics. Finally, the stamped bracket is assembled with the rail and the size and strength are inspected.

The sheet metal stamping process has many advantages. It can produce high-strength and stable brackets; it can ensure dimensional accuracy, which is conducive to the precise installation of the rail; compared with casting or other processing methods, sheet metal stamping parts are usually lighter, which helps to reduce the weight of the overall equipment; when mass-produced, the stamping process has a lower production cost.