With the increasing sophistication and high performance of technology products, the application of metal screen frames in consumer electronic products such as mobile phones and televisions is undergoing a technological revolution. As an important technology for metal frame manufacturing, sheet metal stamping technology is promoting a leap in design and production efficiency in this field, making the equipment more refined in appearance, more functional, and more optimized in cost control.

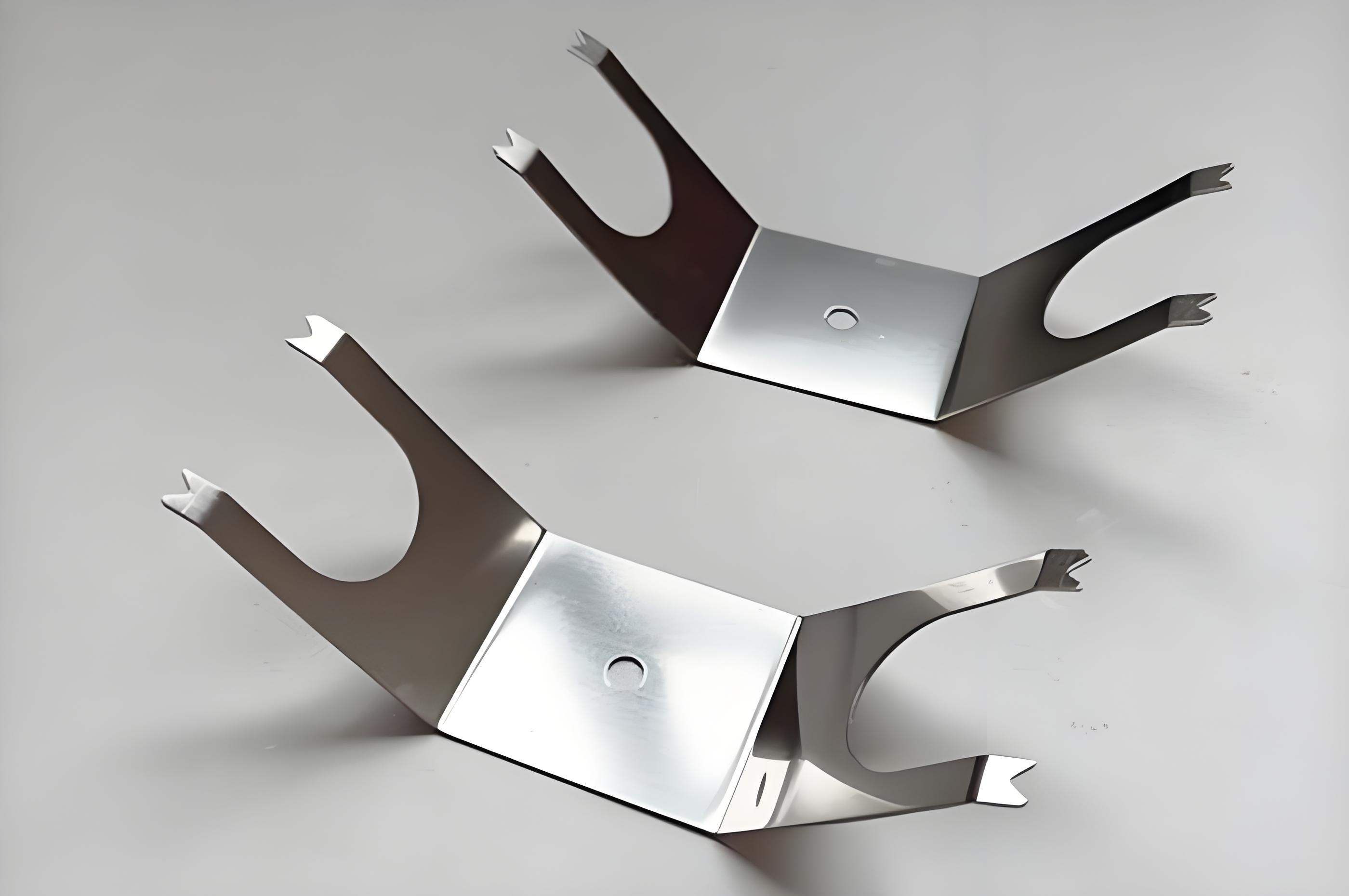

Sheet metal stamping technology has become the mainstream method for the production of metal screen frames with its high efficiency, precision and economy. In traditional metal processing technology, many manufacturing processes rely on manual or more complex mechanical processes, which makes the production cycle long and the cost high. Sheet metal stamping uses high-pressure impact to make the metal sheet into the required shape in the mold at one time. Whether it is the fine curve of the mobile phone frame or the solid support of the TV frame, this process can meet the high standards of modern consumer electronics.

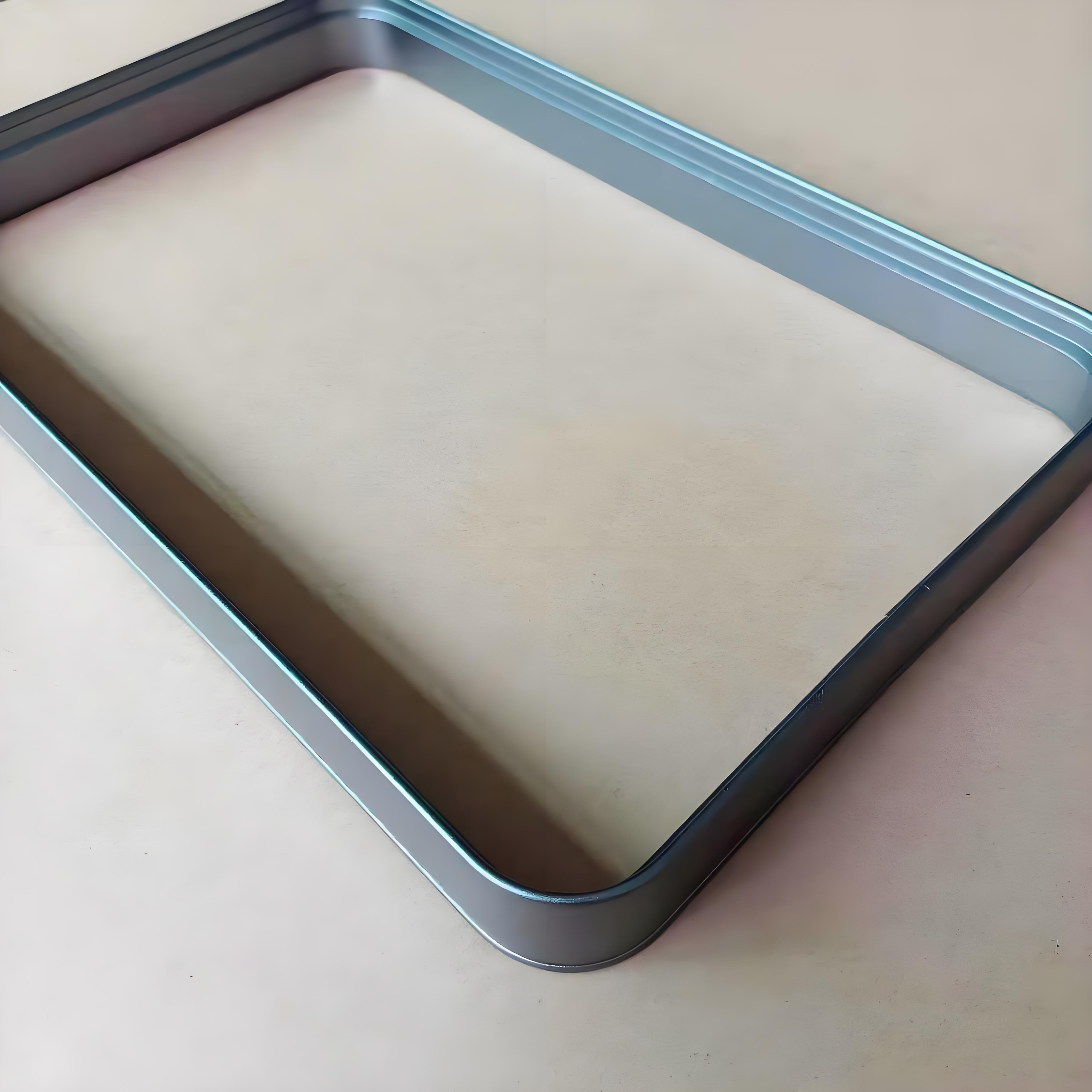

With the continuous development of technology product design, the requirements for the appearance and functionality of metal frames are increasing. Especially in the field of mobile phones and televisions, consumers have higher and higher requirements for appearance, and the thinness, firmness, durability and visual beauty of the product have become the core elements of design.

Taking mobile phones as an example, in recent years, more and more smartphones have adopted ultra-thin aluminum alloy or titanium alloy frames. These materials can not only ensure the sturdiness of the frame, but also greatly reduce the overall weight. Through the sheet metal stamping process, the thickness of the metal frame can be greatly reduced while ensuring strength and stability, further optimizing the feel and convenience of the mobile phone.

The sheet metal stamping process is not limited to molding, but also includes the innovation of metal surface treatment technology. In the past, the frames were mostly treated by single spraying, anodizing or chrome plating, but the improvement of modern technology has made the surface treatment of the frame present more diversified effects. For example, the metal frame surface of mobile phones and TVs can present a unique and delicate texture through the wire drawing process, or use frosting to improve the anti-fingerprint performance. These details enhance the texture and durability of the product.

In the field of televisions, more and more high-end products have begun to adopt a borderless design, that is, the frame is almost integrated with the screen, and the visual effect is very impactful. The advancement of sheet metal stamping technology makes this ultimate aesthetic design possible. Through precise stamping dies and surface treatment technology, the metal frame of the TV not only has to bear the function of protecting the display screen, but also has to seamlessly connect with the glass and screen to create a more futuristic appearance.

As consumer electronic products continue to become thinner, stronger and more beautiful, sheet metal stamping technology is bringing great technological innovation to the manufacturing of metal screen frames. It not only improves manufacturing accuracy and production efficiency, but also promotes breakthroughs in the appearance design and functionality of mobile phones, TVs and other products. In the future, with the further development of intelligence and material technology, sheet metal stamping technology will continue to play an important role in the global consumer electronics industry and help the birth of more innovative products.