Hot-rolled plates use continuous casting slabs or blooming slabs as raw materials. They are heated by a walking heating furnace and descaled with high-pressure water before entering the rough rolling mill. The rough rolled material is cut into the head and tail and then enters the finishing mill. Implement computer controlled rolling, after final rolling, it undergoes laminar cooling (computer controlled cooling rate) and coiling machine to form straight coils. The head and tail of straight hair curlers are often tongue-shaped and fish-tail-shaped, with poor thickness and width accuracy, and the edges often have defects such as wavy shapes, folded edges, and tower shapes. The coil weight is heavier and the inner diameter of the steel coil is 760mm. (Generally, the pipe making industry likes to use it.) After the straight hair roll is processed by head cutting, tail cutting, edge trimming and multi-pass straightening, flattening and other finishing lines, it is then cut into plates or re-rolled, which becomes: hot rolled Steel plates, flat hot-rolled steel coils, slit strips and other products. If the hot-rolled finished rolls are pickled to remove scale and oiled, they become hot-rolled pickled rolls. This product has the tendency to partially replace cold-rolled plates, is moderately priced, and is very popular among users.

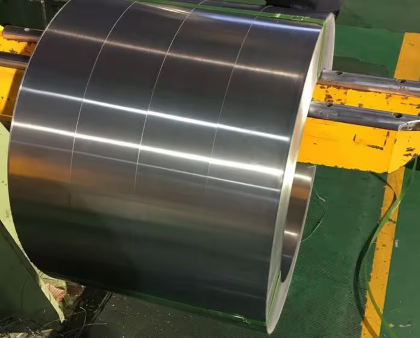

Cold-rolled plates use hot-rolled steel coils as raw materials. They are pickled to remove oxide scale and then cold-rolled continuously. The finished product is hard-rolled coils. The cold work hardening caused by continuous cold deformation increases the strength and hardness of hard-rolled coils. The toughness and plasticity index decreases, so the stamping performance will deteriorate and it can only be used for parts with simple deformation. Hard rolled coils can be used as raw materials in hot-dip galvanizing plants because hot-dip galvanizing units are equipped with annealing lines. The weight of hard-rolled coils is generally 6 to 13.5 tons, and the inner diameter of the steel coil is 610mm.

Generally, cold-rolled plates and coils should undergo continuous annealing (CAPL unit) or bell furnace annealing to eliminate cold work hardening and rolling stress, and achieve the mechanical performance indicators specified in the corresponding standards. The surface quality, appearance and dimensional accuracy of cold-rolled steel plates are better than those of hot-rolled plates, and the product thickness is reduced to about 0.18mm. Therefore, it is favored by the majority of users, and its cost is also higher.