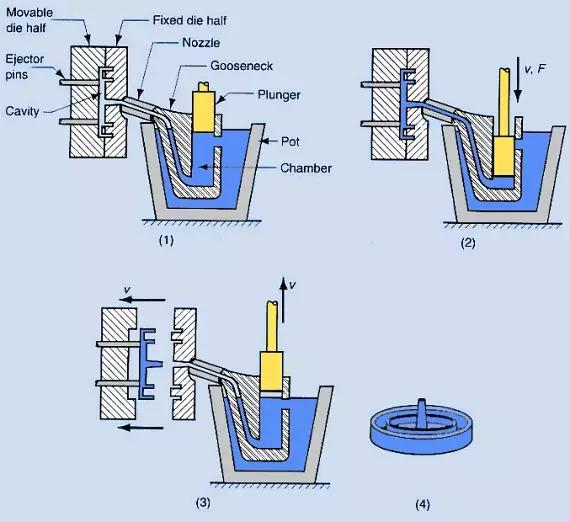

The injection part of the die-casting process uses the energy of the hydraulic system to push the punch, thereby pushing the molten metal into the mold cavity. The molten metal passes through a flow channel called a runner and a smaller cross-sectional area called a gate before entering the mold cavity. The gate accelerates the flow of metal, and it also allows the runner system to be easily separated from the casting. The application of chemicals is indispensable, and they also play an important role.

Punch oil

The performance of the injection system is critical to the production of high-quality die castings (castings must be free of porosity and non-metallic inclusions, while ensuring dimensional accuracy and mechanical properties), controlling the metal pressure during and after filling, and the volume and speed of the metal injected into the mold are critical. It can be said that the absolutely reliable punch system is the soul of successful die casting. And good lubrication performance is the key to ensuring the normal operation of the injection system.

Release agent

During the die-casting process, the mold is continuously heated by high-temperature liquid metal, and its temperature continues to rise. Excessive mold temperature will cause some defects in die castings, such as mold sticking, bubbling, cracking, thermal cracking, etc. At the same time, the mold works in a high temperature environment for a long time, and the strength of the mold material decreases, causing cracks on the mold surface, resulting in mold damage, and ifespan decreases. In order to alleviate or solve the above problems, spraying or coating release agents are often used in the production of workpieces.

Release agent is a functional substance between the mold and the finished product. It can form a uniform release film on the surface of the mold, allowing the molded product to be released, and maintaining the integrity and post-processability of the product.

Fire resistant hydraulic oil

Die casting equipment usually works in high temperature environments. Daily leaks or rupture of pipes and joints and other emergencies make traditional mineral-based hydraulic oils a fire hazard, posing a serious threat to the life and safety of equipment and operators. Therefore, flame-resistant hydraulic fluid should be selected to ensure the stable operation of the hydraulic system under pressure conditions, open flames, and high temperature environments.