The sheet metal stamping panel market has continued to grow in recent years, benefiting from the development trends of multiple industries. Sheet metal stamping technology can effectively achieve high-precision, mass production, and is suitable for manufacturing panels with complex shapes.

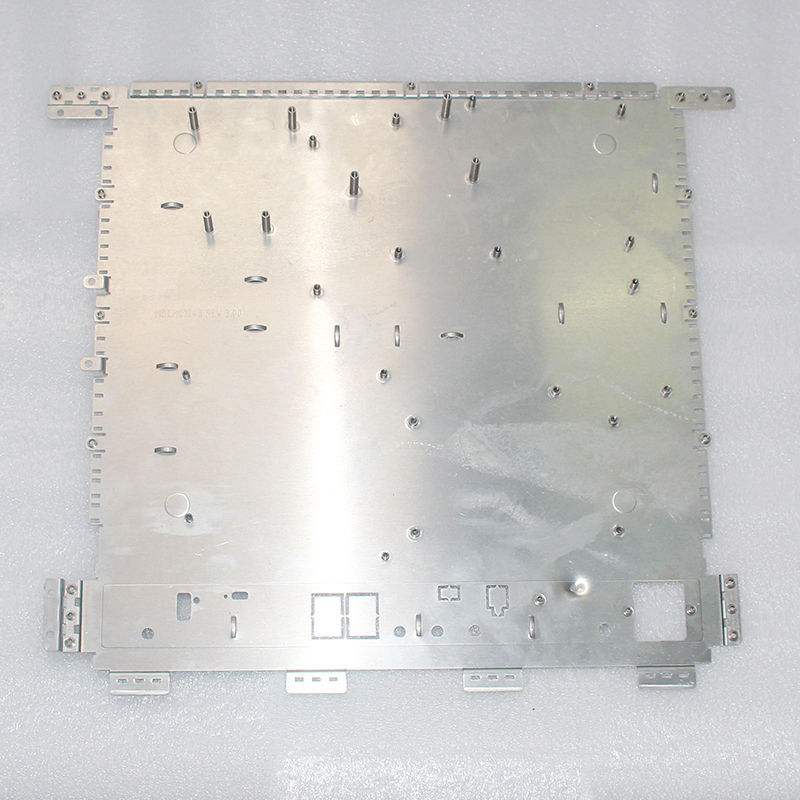

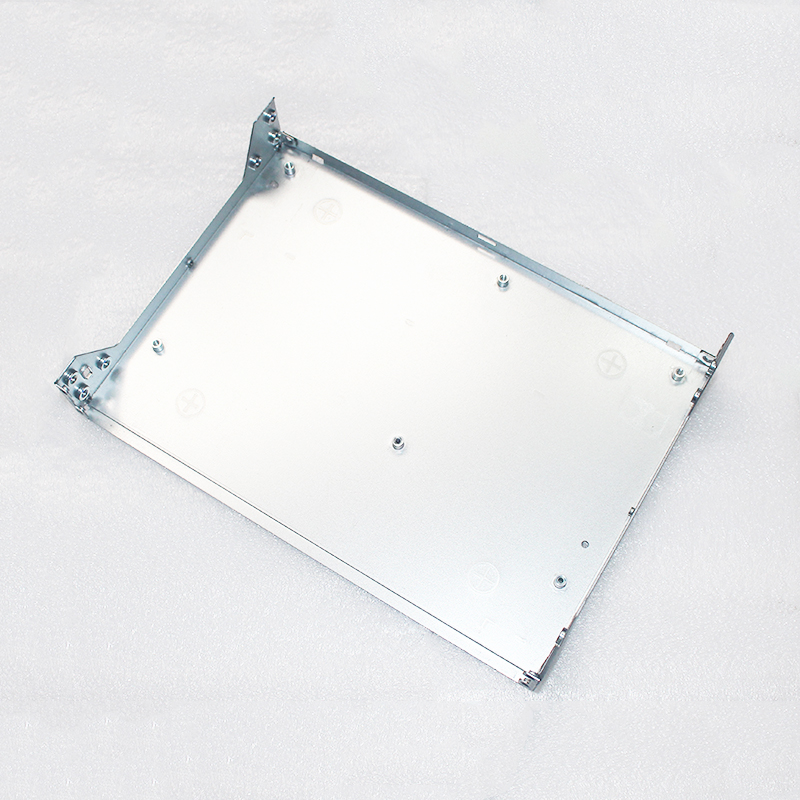

Common ones include electrical panels, which are used for the shells of home appliances (such as refrigerators, washing machines, microwave ovens, etc.), audio equipment, etc., and usually need to have good insulation and corrosion resistance to protect the internal circuits; control panels, which are used in industrial equipment, instruments and meters, and mechanical control systems, carry buttons, display screens and indicator lights for easy operation and monitoring; chassis panels, which are used for the shells of computers or other electronic equipment, are designed to have good heat dissipation, easy installation and maintenance, and usually need to have certain anti-electromagnetic interference capabilities; automotive panels, which are used for automotive dashboards, door panels, etc., need to have wear resistance and aesthetics, and meet safety standards and be able to withstand high temperatures and humidity; air conditioning panels, which are used for air conditioning shells and control panels, need to be weather-resistant to prevent dust and moisture from entering, and also need to be beautiful and in line with the interior decoration style; furniture panels, which are used for the surfaces of furniture such as desks and lockers, require to be beautiful and easy to clean, and also need to have certain durability and strength.

The widespread application of sheet metal stamping panels is mainly due to its high precision and mass production capacity, which can effectively reduce costs and meet the design requirements of different products. There are also many options in material selection and surface treatment to meet the use requirements of different environments. With the advancement of Industry 4.0 and intelligent manufacturing, the sheet metal stamping panel market will face more opportunities. Enterprises need to pay attention to technological innovation, changes in market demand and environmental protection policies, and flexibly adjust strategies to adapt to the market environment.